Formalising Accountabilities Across the Product Value Chain

CLIENT

Tech IP Company

ABOUT THE PROJECT

A semiconductor and software design company based in the UK hired Enfuse Group to formalise their process accountabilities across the Product Value Chain from ‘idea’ to ‘end-of-life’ for a product. In parallel, Enfuse group identified inefficiencies within their end-to-end process utilising process excellence methodologies.

THE CHALLENGE

The client’s main challenge was a lack of clear vision on how their company operated to deliver products, from idea to end-of-life. With no transparent accountability processes in place, it became increasingly hard to pinpoint what the issues were, where they occurred and who was accountable for them.

High-level accountability across the product value chain and the product’s entire lifecycle had to be tailored to establish a clear path to process ownership, efficient handoffs, and process quality monitoring.

THE ENFUSE APPROACH

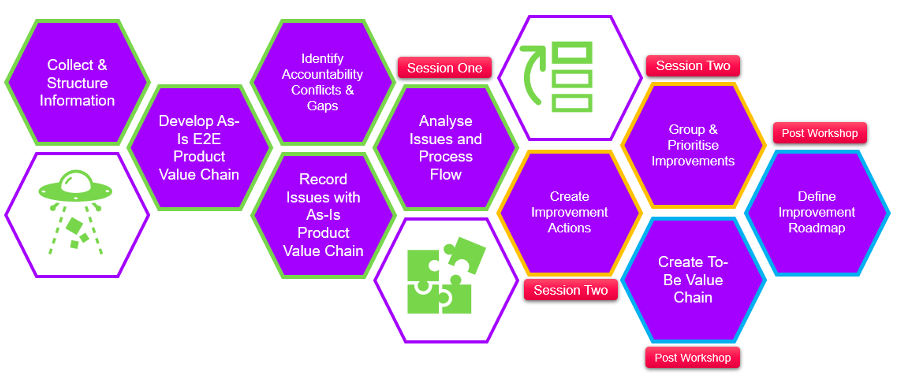

We kicked off the project by collecting relevant information through discovery sessions. Here we interviewed the Subject Matter Experts from various functions, while also leveraging an APQC framework to determine the processes that make up their end-to-end product value chain. As well as defining their process structure, we also asked each function to claim accountability for the processes they believed their team to be accountable for.

In parallel to this, we discussed the issues each function faced while carrying out their processes within the Product Value Chain. All these issues were recorded in an issue and improvement register that constituted a key end-deliverable. We ensured we obtained a view from every key player involved in the core operating processes and developed a thorough understanding of the client’s priorities, issues and improvement ideas.

After completing the discovery sessions, we incorporated the support functions that touch base with the core operating processes to determine where the key communication points occurred.

Our experts found various processes that nobody claimed accountability for, creating a gap, and others where more than one team had claimed accountability for, resulting in a conflict.

The issues, accountability gaps and conflicts were analysed in an improvement workshop. Here we identified the root causes by asking, ‘why, why and why again’. Once the root causes had been agreed, we brainstormed improvement ideas on how to address these issues.

By taking the subject matter experts along the journey, they began to own the improvement initiatives in the form of work packages, which are mini improvement projects that address more than one issue identified. These work packages formed part of their annual improvement roadmap and many of the initiatives were incorporated into the team’s key objectives for the year.

The accountability gaps and conflicts were resolved through discussions with the executive management board. Once theses hurdles had been addressed, we were able to communicate and embed these clear accountabilities to the wider organisation.

THE OUTCOMES

At the end of the project we had achieved the following:

Created a high level end-to-end Product Value Chain, which cut through functional silos, representing how the organisation operated from idea to end-of-life

Assigned accountabilities to each process that made up the Product Value Chain

Created a RACI Matrix to display these accountabilities

Identified and resolved 26 accountability gaps or conflicts

Identified 34 issues across the product value chain

Completed a root cause analysis

Created 23 improvement projects in the form of work packages

Generated visibility that cut through functional silos and highlighted the importance of early communication in issues spanning downstream and upstream activities.

By resolving the accountability gaps and the issues within the product value chain, we were able to identify what the ‘To-Be’ process should look like, allowing the organisation to deliver higher quality products more efficiently through an actionable improvement roadmap.